The Impact of Automation on Manufacturing Jobs

Automation in manufacturing has revolutionized the way products are produced. By utilizing advanced technologies such as robotics and artificial intelligence, manufacturers have been able to increase efficiency, reduce errors, and improve overall productivity. This shift towards automation has not only streamlined processes but has also paved the way for enhanced product quality and consistency.

Moreover, automation has enabled manufacturers to meet the growing demands of consumers in a more timely and cost-effective manner. With the ability to run continuously, automated systems have significantly reduced production times, allowing companies to bring products to market at a quicker pace. As a result, manufacturing facilities have become more agile and adaptable to changing market trends, giving them a competitive edge in the industry.

The Evolution of Automation in the Manufacturing Industry

Automation in the manufacturing industry has been a game-changer over the past few decades. Companies have increasingly turned to automated processes to improve efficiency, accuracy, and productivity. This shift has led to significant advancements in technology and has reshaped the way products are manufactured globally.

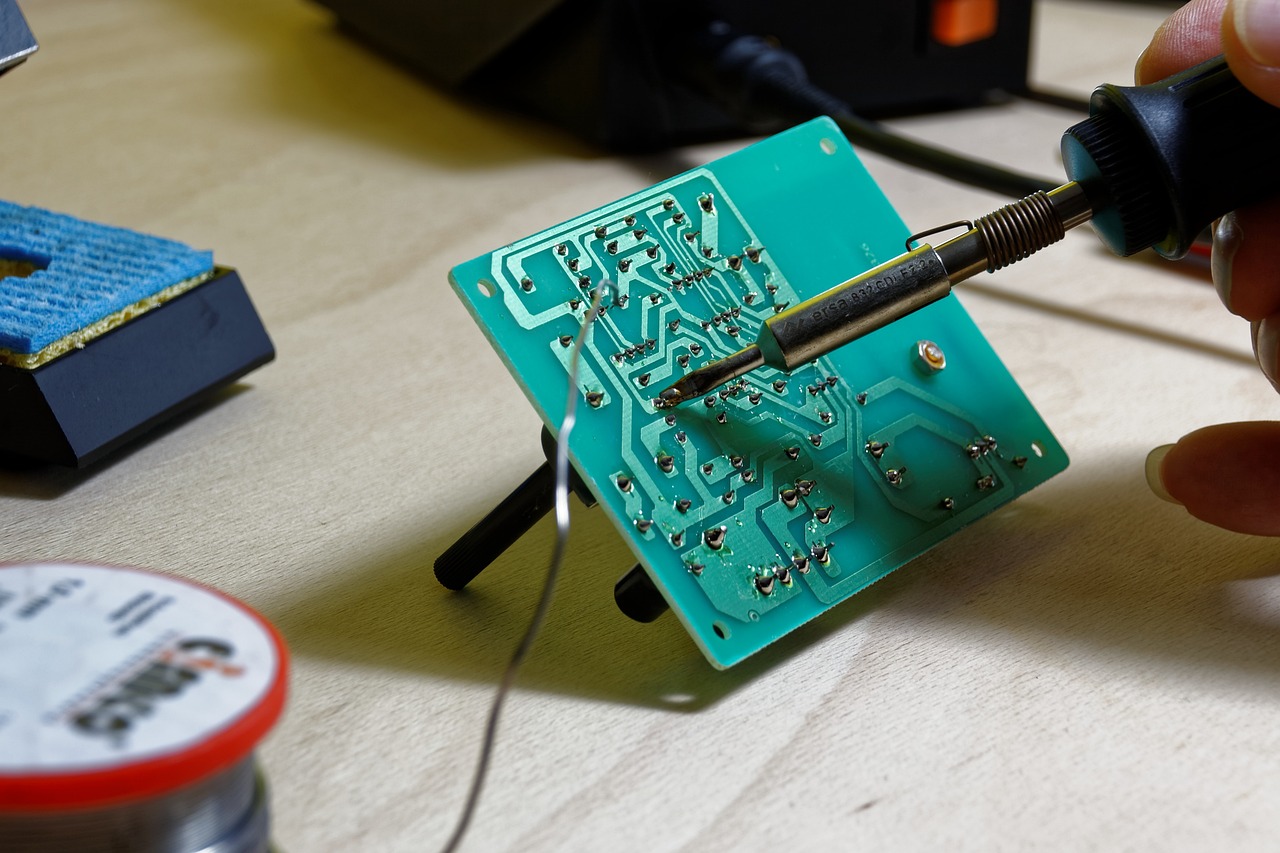

From the introduction of robotic arms on assembly lines to the implementation of sophisticated artificial intelligence systems, the evolution of automation in manufacturing has been revolutionary. These advancements have not only streamlined production processes but have also created new opportunities for innovation and customization in manufacturing. The future of automation in the manufacturing industry is dynamic and holds the potential to further revolutionize the way goods are produced and distributed.

Challenges Faced by Workers in Automated Manufacturing

Increased automation in the manufacturing sector has revolutionized the industry, offering numerous benefits such as enhanced efficiency and productivity. However, this shift towards automation has also brought about new challenges for workers. One primary challenge faced by workers in automated manufacturing is the need to acquire new skills to operate advanced technologies effectively. As machines take over repetitive tasks, workers are required to adapt and upskill to handle more complex operations, creating a learning curve that can be demanding.

Moreover, the implementation of automation in manufacturing processes has raised concerns about job security among workers. With machines being capable of performing tasks faster and more accurately than humans, there is apprehension about the potential displacement of workers. This uncertainty about the future of their roles and the fear of being replaced by machines can lead to increased stress and job dissatisfaction among workers in automated manufacturing environments.

• Workers need to acquire new skills to operate advanced technologies effectively

• Adapting and upskilling is necessary due to machines taking over repetitive tasks

• Learning curve can be demanding for workers in automated manufacturing

• Concerns about job security arise with automation in manufacturing processes

• Machines capable of performing tasks faster and more accurately than humans

• Apprehension about potential displacement of workers leads to stress and job dissatisfaction

What is automation in manufacturing?

Automation in manufacturing refers to the use of machinery and technology to perform tasks that were traditionally done by human workers.

How has automation evolved in the manufacturing industry?

Automation in the manufacturing industry has evolved from simple mechanization to advanced robotics and artificial intelligence systems.

What are some challenges faced by workers in automated manufacturing?

Some challenges faced by workers in automated manufacturing include job displacement, lack of training for new technologies, and concerns about job security.

How can workers in automated manufacturing overcome these challenges?

Workers in automated manufacturing can overcome these challenges by investing in training programs to learn new skills, staying updated on industry trends, and being adaptable to new technologies.